NAVAL & POWER

Curtiss-Wright’s Naval & Power segment provides leading edge technologies that are relied upon to enhance our customers’ safety, reliability and performance in the most demanding environments. We have supported the naval defense market for more than 150 years and today provide high-performance pumps, valves, motors and generators that are integral to powering the U.S. Navy nuclear fleet. We have been in the commercial nuclear market for over 50 years, working closely with the power industry and currently operate an installed base of products at all nuclear plants operating in the U.S. and at many international facilities. We are supporting the drive to carbon-free energy and energy independence, which promotes the need for nuclear innovation and safety, and advanced products, to enhance nuclear plant efficiency and reliability. We supply critical reactor coolant pump technology for next-generation commercial nuclear reactors, most notably for the Generation III+ AP1000 reactor, and are well positioned to support Gen-IV projects including Small Modular Reactors (SMRs) and Advanced Reactors (ARs).

For the defense market, we support an array of ship building programs with pumping, power and propulsion technologies operating at the heart of nuclear submarines and aircraft carriers; instrumentation and control systems; auxiliary systems; and shipborne aircraft and helicopter landing systems. Curtiss-Wright has significant mission critical content on every U.S. Navy submarine and aircraft carrier. We are a preferred supplier of generators, secondary propulsors, pumps and valves used in the nuclear propulsion system. For the U.S. Navy’s next generation aircraft carrier, a Curtiss-Wright energy storage rotor is a critical component of the Electromagnetic Aircraft Launch System, which is replacing the legacy steam catapult. In addition, our innovative low inertia motor for the Advanced Arresting Gear enables more efficient arrest and recovery of aircraft on carrier decks.

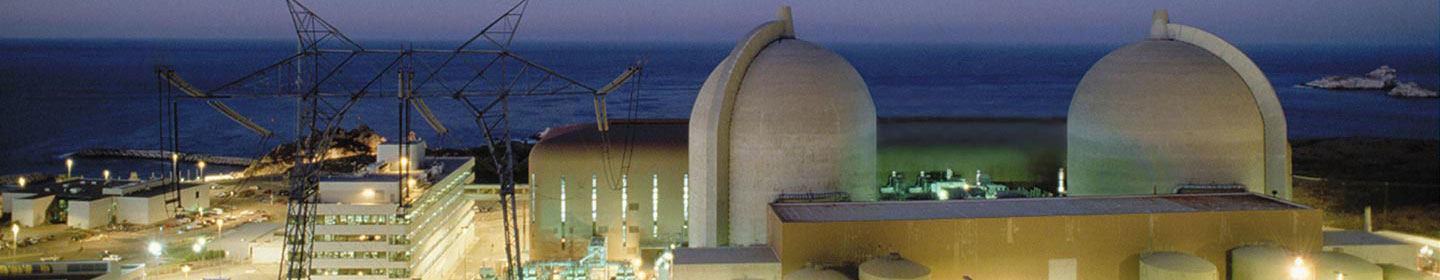

For the commercial nuclear power market, Curtiss-Wright maintains one of the leading distribution networks in the nuclear industry. Our commitment to supporting safe, reliable and high performance products in the commercial nuclear power industry is evident in the Company’s portfolio of more than 150 available technologies. Whether it is currently operating generation stations or new build plants, our technologies support commercial nuclear power operators globally in the safe and efficient production of clean energy and we have done so since the very start of this industry.

Nuclear plant operators require support of their installed base equipment, particularly in the areas of obsolete parts, spent fuel storage and technologies to enhance generating efficiency. At the same time, it is critical to minimize the amount of time a nuclear plant is offline and to ensure that all activities are conducted with the utmost regard for unwavering personnel safety with minimal radiation exposure, as well as enhanced attention to reactor safety. Curtiss-Wright supports each of these vital goals by offering a wide range of critical hardware and services for auxiliary functions, particularly for product obsolescence solutions. These include fastening systems, specialized containment doors, airlock hatches, electrical units, bolting solutions and enterprise resource planning. Moreover, U.S. utilities are dealing with an uncertain long-term storage solution for spent nuclear fuel that is currently stored on-site in spent fuel pools. Through acquisition, we invested in industry leading technology for unique spent fuel pool products, services and analysis that deliver profound value for these customers.

We are a critical supplier to the Westinghouse third generation AP1000 nuclear reactor. Each new AP1000 nuclear reactor uses four of our unique Reactor Coolant Pumps (RCPs) to circulate coolant water through the reactor vessels, ensuring the plant’s safety. With a 60-year design life and virtually maintenance free, our pumps – which are among the most technically advanced in the world - are vital to sustaining a plant’s safety system. The market response for this next-generation reactor has been strong and continues to grow. In the Gen IV market, SMRs and Advanced Reactors have strong U.S. Government support with $3.2B earmarked for advanced nuclear through the Department of Energy’s (DOE's) Advanced Reactor Demonstration Program (ADRP), and Curtiss-Wright is actively engaged and pursuing business on all major designs.

Curtiss-Wright is also a leading provider of high performance valves and related products for safe, reliable and efficient processing to the defense, energy and general industrial markets. We are a premier supplier of highly engineered, critical service valves to the U.S. Navy nuclear fleet, the global nuclear power generation industry and the oil and gas market, most notably to oil producing applications at offshore oil rig installations. Our next generation pressure relief valve technology ensures that our customers can remotely monitor and assist in the accurate reporting of emissions events. In addition, our leakless smart valves eliminate the risk of potentially harmful and polluting emissions from oil refineries and petrochemical plants, where the processing of crude oil, natural gas and petrochemicals creates significant pressures that affect plant equipment.